Completed welded components can be located in practically any type of type of metal product that you can identify in day-to-day life. It's made use of in pipe-making, ductwork, auto production, bike-making, steel-building, and extra. Special band saws for cutting steel have actually solidified blades and feed devices for also reducing. Rough cut-off saws, likewise called cut saws, resemble miter saws but have a steel-cutting rough disks. Easily gain access to valuable market sources currently with complete accessibility to the electronic edition of The Fabricator en Español. Quickly gain access to important industry resources currently with complete access to the electronic version of The Tube and Pipe Journal.

Our Construction Chauffeurs: Top Quality And Consistency

These materials for sheet metal construction normally can be found in determines with 0.006 ″ to 0.75 ″ (0.015 to 1.905 centimeters) thickness. In this list, you have actually experienced preferred sorts of metal fabrication like spreading, creating, metal marking, cutting, extrusion, and welding. As mentioned previously, these methods are made use of for crafting different steel elements that are made use of in a selection of applications. They're likewise optimal for customized parts that can match the choices of the end-user. Steel producers usually deal with a variety of basic materials that might include various kinds of steel such as plate steel, broadened metal, welding cables and poles, and cast steel. Essentially, manufacture is an important step in developing any kind of completed metal part or framework.

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year - New Orleans CityBusiness

1.+Fastest+Growing+Companies+2024%3A+SSE+Steel+Fabrication+increases+revenue+193%25+year-over-year.

Posted: Tue, 07 May 2024 19:37:10 GMT [source]

Commercial Paint

The health problems arising from unpleasant blasting directly connects to the products utilized in the process. The dusts from the blowing up material as well as the blasted object can be extremely harmful if breathed in. OSHA has a number of guidelines in place to secure the wellness and welfare of welders and cutters. Besides personal protective devices, OSHA suggests crafted controls that accumulate dust, smoke and fume at resource.

Light Weight Aluminum:

The capability of these firms to make modern-day investments that enable them to preserve a variable result is the key to sustaining customer diversity. Metal construction industry has wide applications throughout a great several sectors and consumer items. Requirement basic materials used include plate metal, fittings, castings, created and expanded metal, sectional metal, flat metal, and welding cable.

The machine shops examine the schematic, calculate the expense of manufacturing and reply with both price and lead time. People have actually been extracting and machining steel for the previous 10 millennia, as confirmed by a copper pendant excavators discovered in north Iraq that dates back to regarding 9,000 BCE. Manufacture shops as we understand them today started to exist around the Industrial Transformation, when sheet metal was in much greater demand than previously. The development of the hydraulic press, which allowed producers to use unprecedented stress to pieces of metal, changed the steel manufacture industry.

Since architectural steel is carbon steel, it includes approximately 2.1% carbon by weight. High-strength and low-ductility products are generated when the carbon material of steel is boosted. The necessary carbon amount or material will certainly rely on how the steel will be made use of. The safety and high quality criteria for making structural steel differ by local and national standards.

Similar to various other making processes, both human labor and automation are typically made use of. A fabricated product may be called a fabrication, and shops specializing in this sort of work are called fabulous shops. Steel fabrication is the procedure of structure makers and frameworks from raw metal products. The procedure includes cutting, melting, welding, machining, forming, and setting up to create the end product.

Machining is a subtractive shaping procedure that gets rid of unwanted product to develop a type. Casting is widely accepted as the go-to procedure for mass-produced items where the same mold can be utilized over and over once again with minimal variance in the last end result. MIG, metal inert gas welding, uses a system featuring a strong cord electrode that forms an arc in between this electrode and the material being functioned, and the parts are then merged with each other. We take every action possible to make certain the lowest cost with the finest.

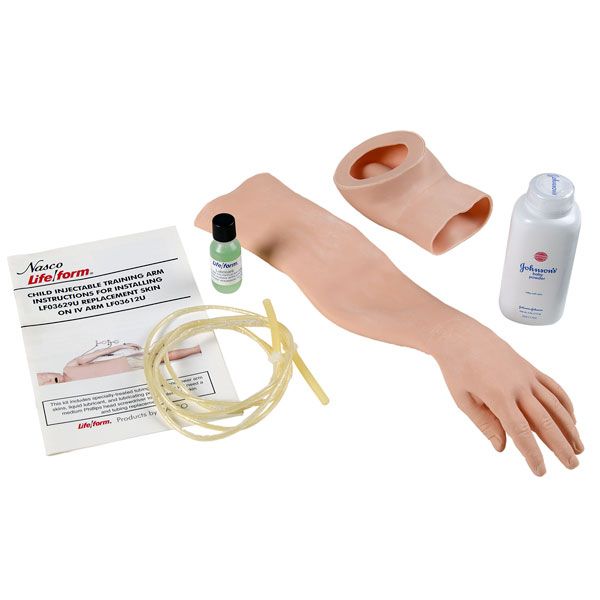

In addition, this is a superb material for welding because of the material's ease of bending. As a result, stainless-steel is regularly made use of in applications needing rust resistance. Milling gets rid medical training supplies of added product from a raw metal component using specialized multi-point cutting devices. This treatment can be executed manually or with the help of a CNC milling machine. Milling, generally, is much more frequently utilized as an additional metal fabrication treatment. This step concentrates on verifying if all layout specifications are met throughout the steel product construction.

Easily accessibility useful market resources currently with full accessibility to the electronic version of The Welder. Quickly gain access to important sector sources now with complete accessibility to the electronic edition of The Producer. With several presses and flexing tools and a wide variety of tooling we can bend almost any kind of part and account. Spray paint additionally includes harmful steels and chemicals that present extra wellness problems when inhaled.